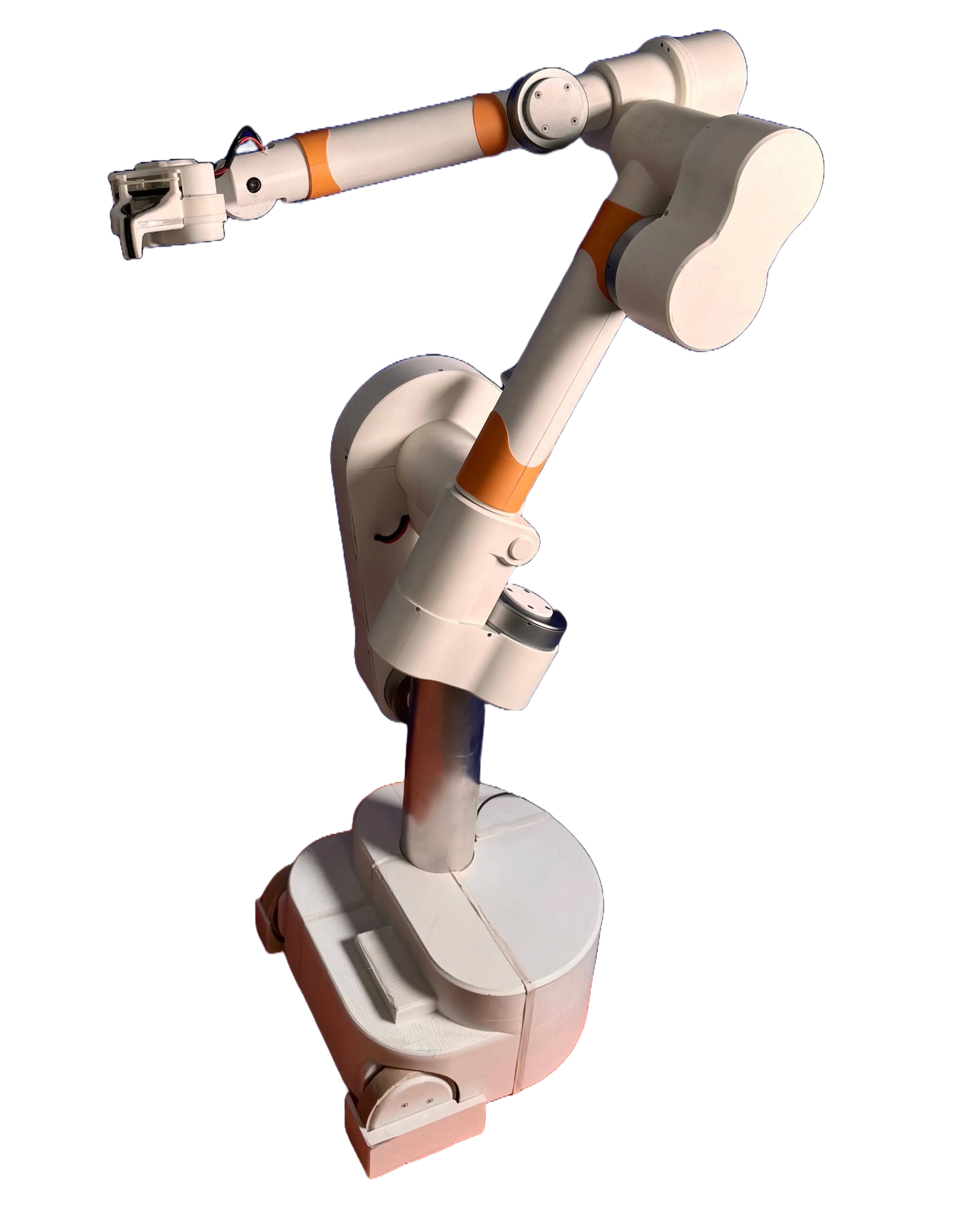

Robot arms for

Animo arms combine the latest motor technology with our proprietary actuator design, making them affordable and inherently safe around humans.

Starting at $10,000.

Built for contact

Today's commercial robotic arms are like sledgehammers: strong and immovable. They were optimized for factories, but as physical AI advances and we deploy robots for non-industrial tasks, like dishwashing or food prep, we need arms that are both strong AND gentle.

Ultra Lightweight

At just 10kg and with low inertia actuators, Animo arms are effectively ~10x lighter during impacts, minimizing collision forces.

True Backdrivability

Low-inertia, low-friction hardware combined with active gravity and friction compensation makes Animo arms easy to backdrive.

High-Fidelity Force Control

Integrated joint torque sensing in all axes with 0.18N force repeatability makes it easy to perform contact-rich tasks.

Technical Specifications

Ideal Applications

Laboratory Automation

Food Service

Cleaning

Robot Learning Research

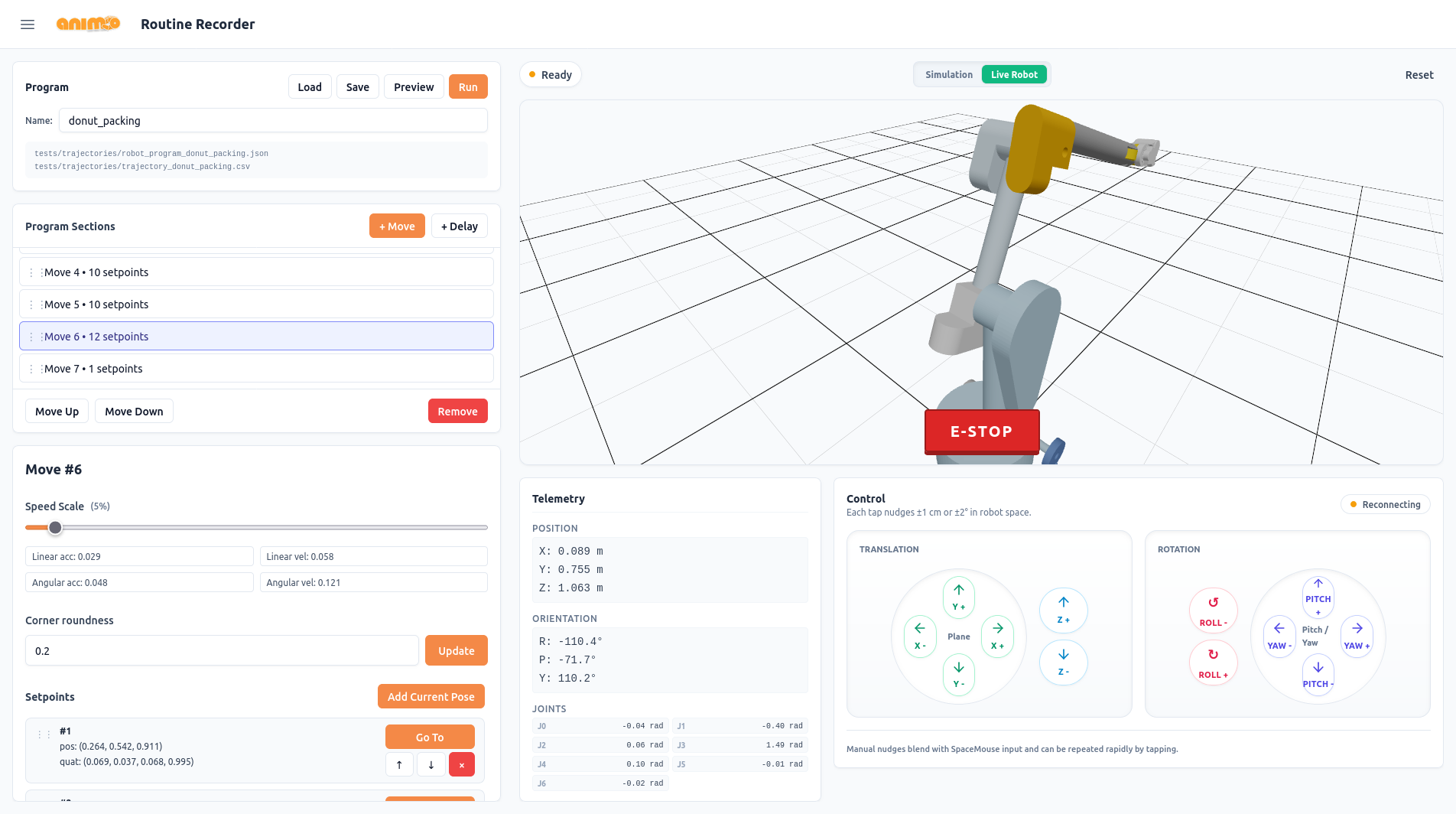

No-Code Programming for Complex Routines

Visual Trajectory Design

Create multi-step routines using motion primitives and gripper setpoints. Adjust speed, acceleration limits, and more for each movement individually.

Virtual Twin

Toggle between simulation and live hardware control with a single click. Verify kinematics and reachability in the 3D viewer before moving the physical robot.

Precise Telemetry & Control

Set the end-effector pose with incremental controls, 3D spacemouse, or backdriving the robot arm itself. Save exact poses as waypoints while monitoring real-time joint telemetry.

Full low-level access with modern SDKs

Perfect for researchers needing raw access to joint space gains, torques, safety settings, and more.

Unified SDK Access

Stream end-effector poses or command individual motor torques from a single Python interface.

Native Safety Primitives

Experiment safely with built-in soft stops, hold modes, and explicit safe-pause commands. Can be disabled as needed.

Seamless Sim-to-Real

Low-friction and low-inertia hardware is easier to model. This, combined with precise force sensing lead to more accurate simulation of real-world behavior.

Real-Time Control

100Hz high-level control loop optimized for low latency. Low level joint impedence controller runs at 8 kHz.

Transparent Physics

Each unit is calibrated to accurately model gravity, friction, and other system dynamics.

from animo import Robot

with Robot(use_hardware=False, gui=True) as robot:

# 1. Move to a nominal joint configuration (same call works in sim and hardware)

robot.move_joints(

q=[0.0, -0.5, 0.0, 1.5, 0.0, 0.0, 0.0],

speed=2.0,

blocking=True,

)

# 2. Change default joint-space gains at up to 100 Hz

robot.set_joint_gains({

1: {"K": 4800.0, "D": 85.0},

3: {"K": 750.0, "D": 13.0},

})

# 3. Custom 100 Hz Cartesian control with velocity + feed-forward wrench

for t, state in robot.control_loop(rate_hz=1000):

X, dX = state.X, state.dX

# Hold pose, drift slowly in +Y, push down with a -10 N Z-force at the tool

robot.command_cartesian(

position=X.pos,

orientation=X.orn,

linear_velocity=[0.0, 0.0, 0.0],

angular_velocity=[0.0, 0.0, 0.0],

# 6D feed-forward wrench [Fx, Fy, Fz, Tx, Ty, Tz] in world frame

feed_forward_force=[0.0, 0.0, 0.0, 0.0, 0.0, 0.0],

)

Want to build with Animo?

We're seeking collaborators for our first early access units shipping February 2026. Secure your spot with a refundable deposit.